One of our clients was dealing with a component that fractured during routine testing. After internal reviews proved inconclusive, it called on IMR to conduct a failure analysis to determine the problem.

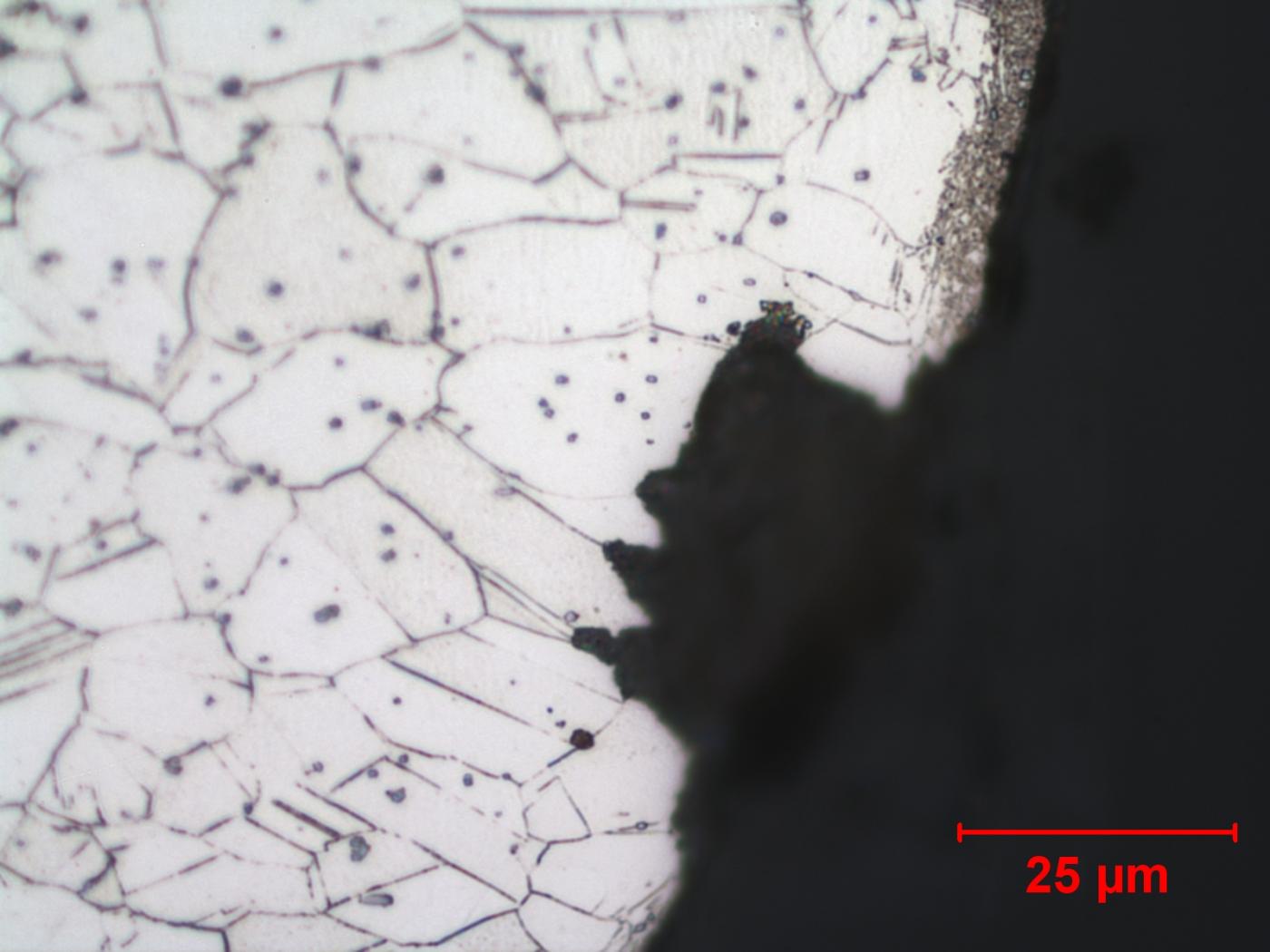

We began by collecting particulate samples from inside the failed component, using SEM-EDS to identify what was present. We soon discovered that the embedded particles were composed of alumina, silicon oxide, and carbides. We also detected chlorine within the component. Since we knew that the part was exposed to high-temperature steam with hydrogen, we quickly inferred from the pitting we observed that the root cause was hydrogen embrittlement.

Solutions to the problem include evaluating the cleaning process, increasing the frequency of inspections for pitting, and making the part with thicker walls. IMR was able to provide straightforward answers, enabling our client to mitigate the issue.

For more information, download our Failure Analysis Case Study Guide.