We received two sections of 304 stainless steel pipe along with samples of insulation, strapping, two process fluids, and a water sample from the DI system used to mix the fluids for failure analysis.

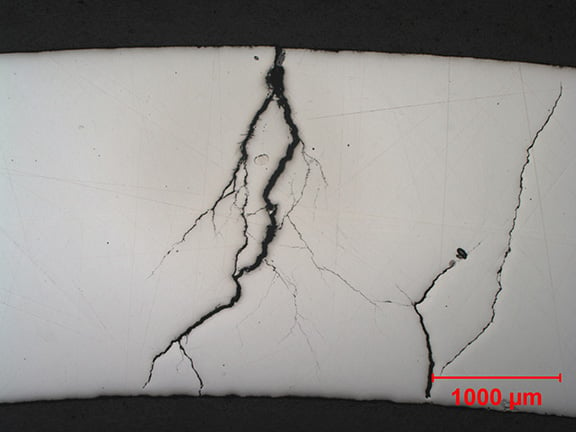

Ion chromatography (IC) testing revealed that the DI water sample contained 9 ppm of chlorides that could cause corrosion. The silicone-based piping insulation also contained both sodium and chlorine. If these elements are trapped against stainless steel in a moist environment, stress corrosion cracking (SCC) can occur, as it did here. For more information, download our Failure Analysis Case Stude Guide