There are myriad reasons why a non-metallic material might fail; These vary widely based on the specific material, the application for which it is intended, and the environment to which it is exposed. Thorough fatigue testing is the best way to determine in advance if a material will be suitable for specific operational conditions. When necessary, failure analysis can also determine why a design failed after the fact.

Methods of Investigation

Because there is no A-to-Z, step-by-step guide for analyzing a material failure, a knowledgeable, skilled team of chemists, engineers, and lab technicians is critically important to ensuring an accurate analysis.

The investigation begins by comprehensively interviewing the customer to determine the exact failure conditions — in a sense, discussing the “who, what, when, where, and how” of the failure in an effort to discover the “why”, or the root cause behind the failure. Regardless of material classification, this portion of the investigative process is relatively the same. The analyst needs to understand exactly what happened leading up to and during the failure before determining the best initial testing methods.

The testing protocols the analyst utilizes after this investigative phase is determined by the specific material and the signs of failure it displays, because different non-metallic materials will fail in different ways. Understanding the varied failure options for each material, and what might cause them, helps an investigator continually narrow their focus until they can determine the official failure cause. Typical non-metallic materials and their associated failure types are outlined below.

The chemist will investigate the test material for signs of aging (fluid and thermal), cracks and fractures, or exposure to chemicals. Polymers often fail after unexpected exposure to chemicals, or because the wrong polymer was chosen for the specific application.

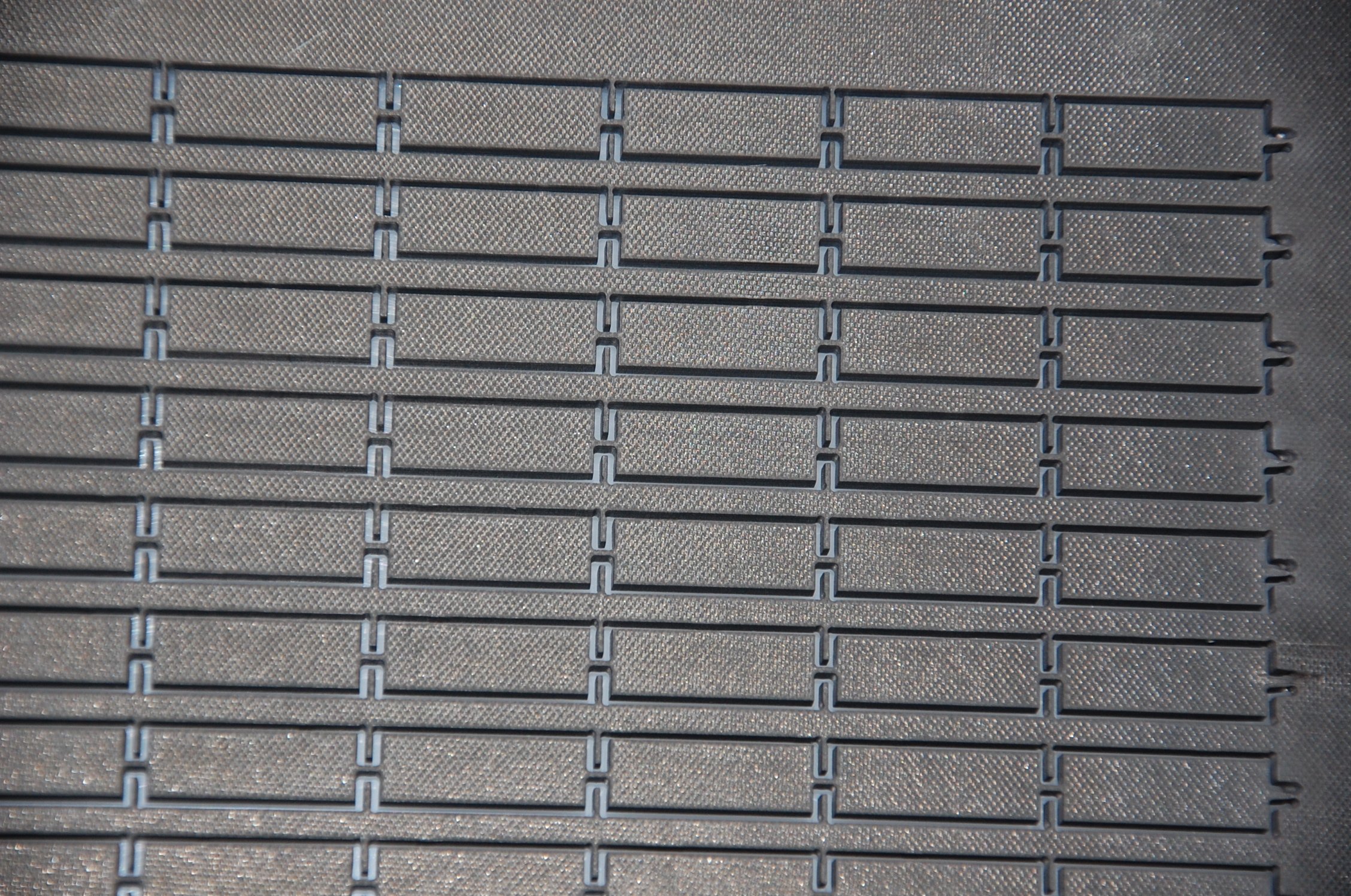

Fiber-reinforced composite samples will be examined for broken fibers, cracks, or delamination. Because of their high strength-to-weight ratio, composites are commonly used in aerospace and other high-stress environments. Improper manufacturing practices, poor material choice, or overestimation of a material’s capacity can lead to failure over time.

Failed coatings experience erosion, cracking, or delamination if they are unsuitable for a particular application. Failure often occurs due to poor adhesion or an incompatibility with the substrate.

Ceramics will be assessed for porosity, fractographic stresses, and thermal tolerances. Since ceramics are often brittle by nature, technicians will analyze chemical compositions, thermal states, or other environmental conditions that may cause erosion.

Once the initial stage of the investigation is complete, more extensive chemical and mechanical testing can begin to pinpoint the exact cause of the non-metallic material failure. A range of chemical analyses, microscopy, fractography, and other physical or mechanical testing methods are available to determine the cause of any symptoms displayed by a given material. In most cases, tests will simulate the environment of the failed sample to observe the failure in real time, which can lead to discovery of the failure cause.

Testing and Analysis from IMR Test Labs

IMR Test Labs offers a wide range of failure analysis testing services for non-metallic materials such as polymers, composites, coatings, and ceramics. Our experienced staff of chemists, engineers, and additional specialists has the capability, knowledge, and advanced tools necessary to analyze an expansive range of materials, enabling us to determine the root cause of any part or material failure.

We don’t just gather data — we have the hands-on expertise and knowledge required to interpret it effectively and get to the root cause of our clients’ problems as quickly as possible. Once we’ve determined the root cause, we then make recommendations for design alterations or potential new materials that will better suit the application. Our end-to-end investigative and analytical process helps manufacturers make informed design choices in selecting the right material for their application.

To learn more about failure analysis, download our eBook, Case Study Guide to Failure Analysis