When preparing testing samples for composites and non-metallic engineered materials, there are many advantages to waterjet cutting.

Using standard cutting tools to cut test samples exposes the sample to the blade’s heat or abrasiveness, negatively affecting the sample’s composition, microstructure and other physical properties. Altering these properties can ultimately affect the accuracy of the test results.

Waterjet cutters use high pressure streams of water and small additives in the form of suspended grit or other abrasives, such as garnet and aluminum oxide. The steady stream of pressurized water and grit keep the temperatures of the materials much lower than other cutting processes require. Since there is no "heat affected zone" (HAZ), the sample’s intrinsic qualities remain stable.

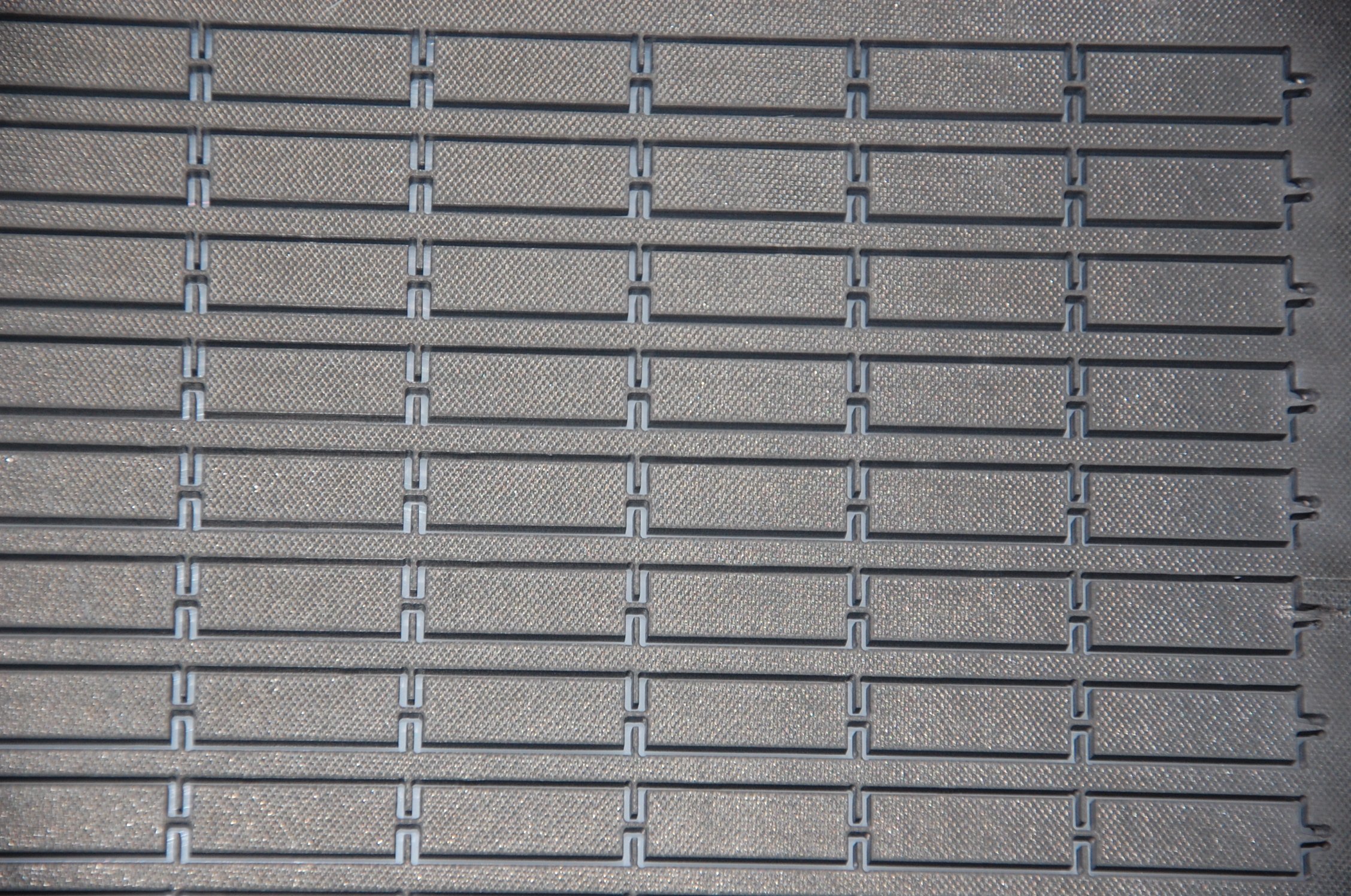

Waterjet cutting is especially beneficial when cutting composites, resulting in smooth edges and marginal material waste. Modern waterjet cutting machines are programmed to accurately perform complex material sample cutting from programmed patterns.

For more information on how to get the most accurate results and analyses, download our latest eBook- Composite Materials Testing in the Aerospace Industry